RUMAR Dental Bearings

All of the bearings that we offer at RUMAR are manufactured by the worlds main bearing manufacturers in the world: myonic®, HQW, Barden, GRW, NMB, NHBB o ESI. All of these are manufactured to ISO* precision standards (bearing standards in the metric system) and ABEC** (bearings that are generally measured in inches)

At RUMAR, we offer the rotor with the exact same characteristics and with the same features specified by the manufacturer for any model of turbine, contra angle, hand-piece or micro-motor. Example: if KaVo places a 660 Turbine on a smooth rotor, cermaic ball bearing, angular contact, torlon cage and closed, RUMAR offers the exact same smooth rotor, ceramic ball bearing, angular contact, torlon cage and closed manufactured by myonic.

* ISO: International Standard Organization.

** ABEC: Annular Bearing Engineers Conference.

What do I need to know at the time of purchase of a dental bearing?

There are 5 fundamental variables to be taken into account when deciding on which dental bearing to purchase:

1.-Model: approximations are not valid. With dental equipment, precision is essential, which is exactly why you should choose the bearing with the right measurements (internal diameter x external diameter x height), external shape (stepped, smooth or flanged), materials, number of balls and with its general characteristics and for the same type of performance outlined by the manufacturer of the instrument in which the bearing will be placed.

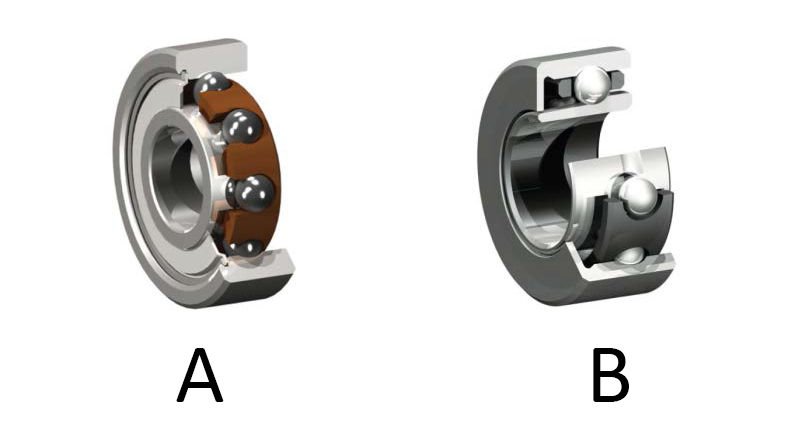

2.-Angular or Deep groove?: the shape of the cage and of the groove in the inner and outer track will determine if a bearing is angular or radial. Knowing if a bearing is Angular / ACBB or Deep Groove / DGBB) is essential to determining the sound level, the level of vibration and ultimately the durability of the bearing. To be able to identify them, we only need to pay attention to the shape of the cage / retainer.

Angular / ACBB: The angular bearings include a complete cage / retainer. Angular implies a lower sound level, lower level of vibration and greater durability. At high speed the angular characteristic is fundamental. Example: bearing B in the picture is angular (complete cage / retainer).

Deep groove: The bearings that are radial include a crown shaped cage / retainer (open on one of the two sides). Deep groove implies a cheaper price and, in cases where the variables level, sound, level of vibration and durability are not the key, it is the best option. In low speed, deep groove is a very good option. Example: bearing A in the picture is radial (crown shaped cage / retainer).

3.-Open, Closed or integral?:

With dental turbines, the bearings are always open on the side that makes contact with the rotor impeller. It is on this side in the majority of turbine models where the lubricant will enter the bearings. In low speed it is more common to find bearings closed on both sides or open on both sides, depending on the model.

Open bearing: will allow easy entry (and exit) of lubricant, but also that of waste from the environment (if any).

Closed bearing: makes it more difficult for the exit of lubricant and the entry of waste on its closed side. Example: in bearing A in the picture, the external side is closed and the internal side is open.

Integral bearing: It makes even more difficult for the exit of lubricant and the entry of waste through the closed side. Example: in bearing B in the picture, the external side is “integrally” closed and the internal one is open.

4.-Ceramic ball or steel ball?:

Ceramic ball: The greater resistance of the ceramic ball at high speeds guarantees better performance and greater durability. It is not optional, if you are above 200,000 rpm, it requires a ceramic ball (this includes the contra angle multipliers).

Steel ball: for lower speeds, since it is not exposed to such high revolutions, the bearing is isolated from the most harmful residues in some cases and because the bearing is exposed to axial forces in other cases, the steel ball bearing is the best option for low speeds (below 60,000 rpm).

5.-Torlon, Phenolic or Steel?: It has to do with the material with which the cages / retainers of the balls of the bearings are manufactured and it is really just a matter of taste.

Torlon: it is more rigid and less permeable than the Phenolic. As a result, it is better resistant to the exposure of waste and abuse but retains a lesser amount of lubricant.

Phenolic: it is more flexible and permeable then the Torlon. As a result, it does not resist the exposure of waste and abuse as well but it retains a greater amount of lubricant.

Steel: it is even more flexible and even less permeable than the other two. It is common is low speeds but could not exist in high speeds.

Rotors Dental Turbines

There are an innumerable amount of manufacturers with compatible rotors worldwide and the quality of the compatible rotors vary from rotors that surpass certain aspects compared to that of the originals all the way to rotors that do not have even a minimum of quality. This is exactly why the word “compatible” says very little about the product and why it is important to know what you are buying.

There are an innumerable amount of manufacturers with compatible rotors worldwide and the quality of the compatible rotors vary from rotors that surpass certain aspects compared to that of the originals all the way to rotors that do not have even a minimum of quality. This is exactly why the word “compatible” says very little about the product and why it is important to know what you are buying.

At RUMAR, we distribute the highest quality of compatible rotors in the market, with certain models even surpassing the durability and performance of the original. As with the bearings, our dental rotors have the exact same characteristics (measurements, distribution, bearings) than that of the original and they are meant for the same performance requirements. In general, all of our rotors have the following charactertistics (even though you can check our website rumarcedeira.com to view a rotors specificities in each of their corresponding tabs):

- myonic ® ceramic bearing with a tolerance class of ABEC7 at the very least.

- Electromagnetically balanced.

- Hardened steel clamp and anti-rust.

- Carbide or steel insert, depending on the model.

- WCC coating for a longer lasting clamp, along with its components

- Aluminum blade without lead.

- Concentricity <0,018mm / Balance < 0,05mg mm.

- Minimum chuck force of 42N.

- Supply includes: toric rings and metallic washers (depending on the model).

- Warranty: 12 months for the clamp.